Started cleaning the timing chest cover. Still needs repair and some modification:

Allso I sealed the magdyno against the housing. Not visible, but yet important.

But I fabricated a fixture for the headlamp. Close, but ok!

The rear subframe is coming along as well:

The rear mudguard brackets welded on:

Looking cool:

But two German sayings happened to come true:

-Wer misst misst Mist. (Who measures measures crap)

-Was nicht passt, wird passend gemacht. (What doesn't fit, is made to)

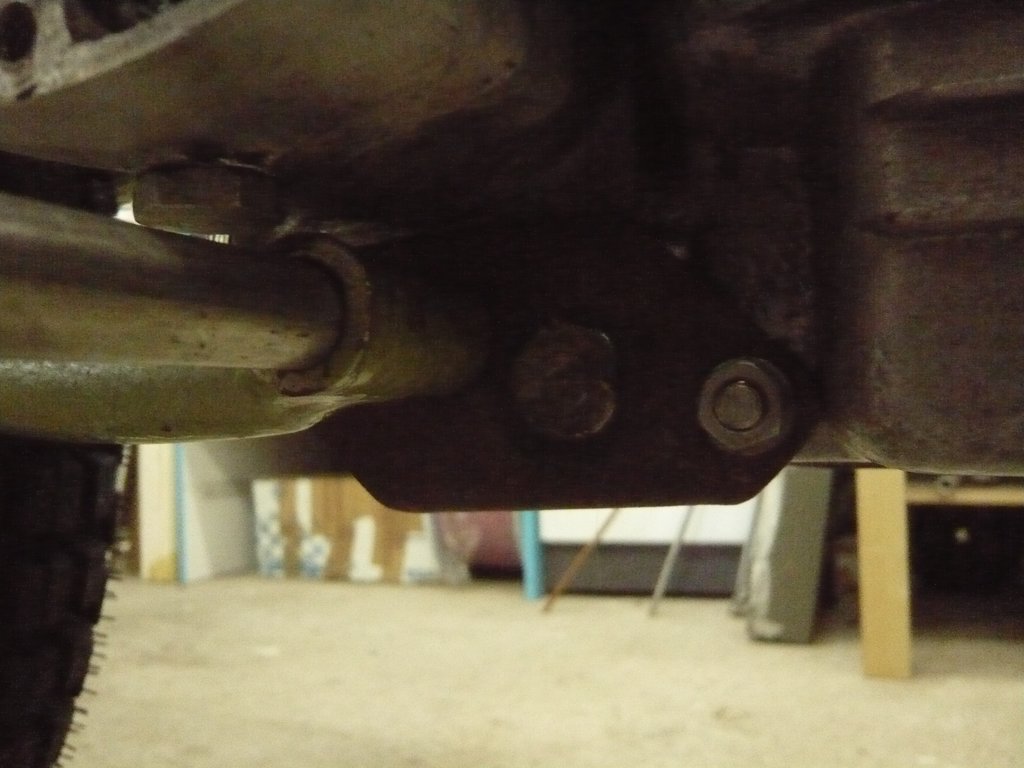

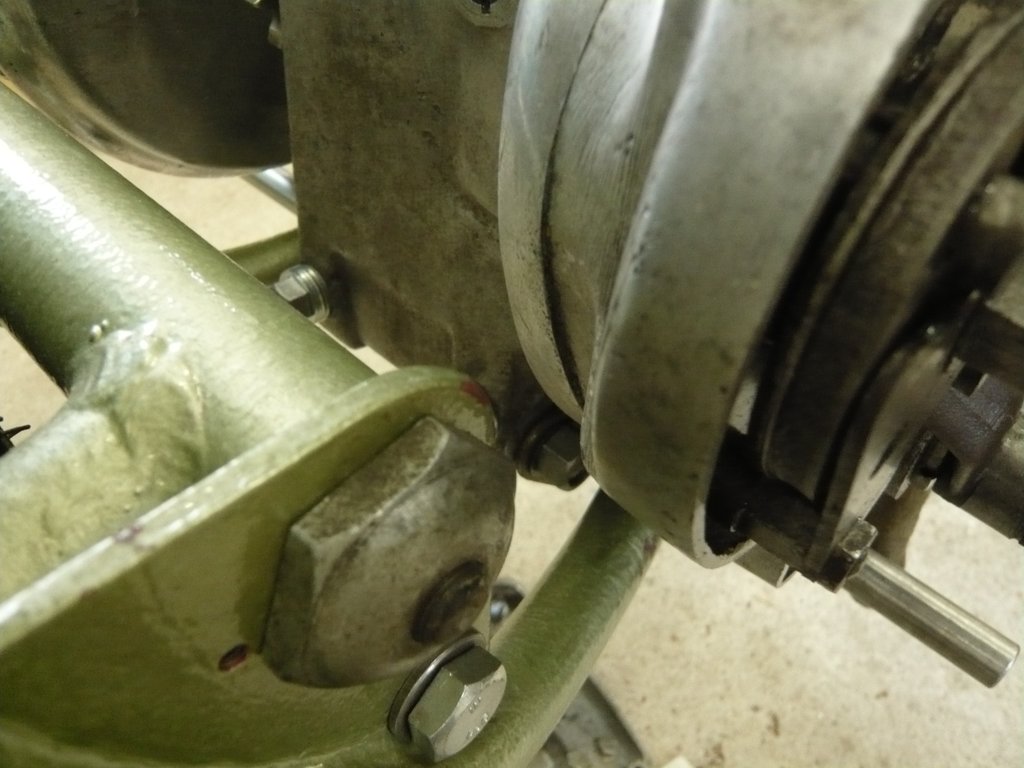

Because the gearbox colided in the rear and the rear rocker cover would not pass the frame. So I had no other option, than to weld some holes, alter the brackets and drill again:

But now it fits. Both in the rear and on top there's enough space:

And on the subframe I added some plates for stiffening as well as for mounting the mudguard's front and the seat:

Unfortunately I don't have any more gas (hardware stores are all closed due to Corona virus) and have to wait to weld the parts. But I think you can guess how it's supposed to look like

So long,

Andreas