Set aside the packaging problems normally associated with having to mount the carb and air filter so high up in a downdraft head configuration, and instead just focus on the performance aspect.

In the 80s and 90s, when the Sound of Singles racing series was in its glorious air cooled, carbureted heyday, as far as I know the hottest engines were the Rotax and Honda 4 valvers using custom downdraft heads (sometimes dual carbed, no less).

Not necessarily downdraft

carbs, mind you, but downdraft

heads.

Just how much better for performance is a downdraught head vs a standard horizontal head?

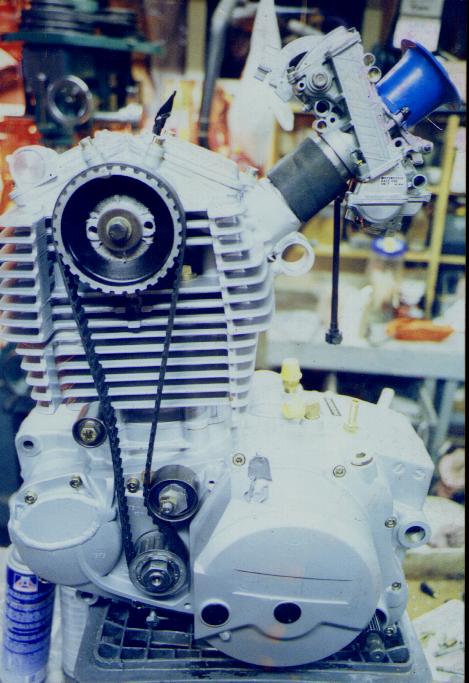

350cc Rotax with a single carb downdraught head

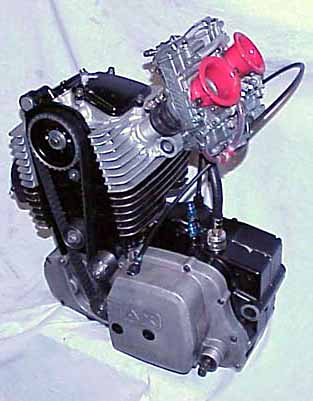

675cc Rotax with a dual carb downdraught head

VS

Standard horizontal sidedraft head