This time just a minor update, but not less important.

First a comparison of the oil pump sindles of the Chief (and other pre-1964 twins) and the Interceptor:

Easy to see, there are two main differences, being the groove left to the rear bearing and a 90° offset of the pump spindle crank pins.

Latter probably, to distribute the load and achieve smoother running. This can't be altered afterwards. The former can! The groove has a coresponding thread in the timing cover to take a bolt with a pivot, securing the spindle's axial position. Without that measure, the spindle can move forward and catch the pump cover, causing the crank pin to break - as happened to my Chief. Marks on other covers are proof, that this is very likely to happen and the touching up by RE shows, this must have been anything but unusual.

But the spindle is hardened and extremely tough, which makes turning impossible, even with ceramic tools. I wasn't able to machine the groove that way. What now? It is possible to work quite accurate with angle grinder and a 1mm cutting disk and so I ground it with just some 1/10mm accuracy (letting the spindle turn on the lathe and wielding the grinder by hand):

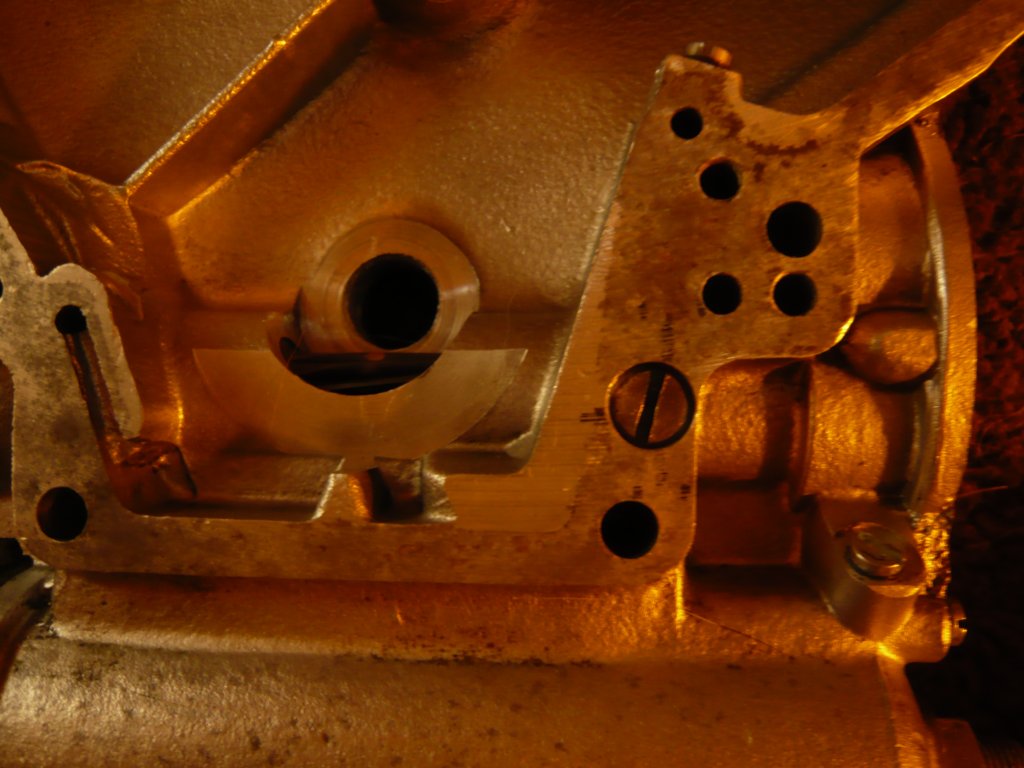

The matching bore was easier to make. That's how it looks like completed:

The spindle has an axial movement of only a few 1/10mm now - enough to allow for easy movement, but too few, to collide with the cover. Now I can be at ease, because the trouble such a damage causes I do not want to imagine and the spindles themselves aren't cheap at all.

So long,

Andreas